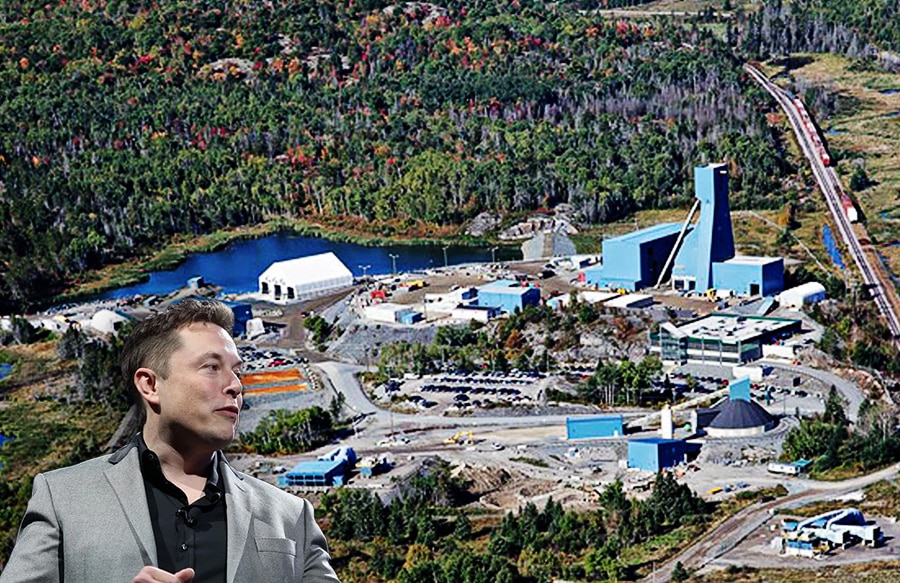

Vale, the world’s top nickel and iron ore producer, has inked a long-term deal with Tesla that will see the Brazilian miner supplying the electric vehicles (EVs) icon with nickel mined in Canada.

Confirming market rumours, the miner said the supply contract fit with its plans to deliver 30% to 40% of Class 1 nickel sales into the fast-growing EV industry.

The Rio de Janeiro-based company, which did not provide details on financials or duration of the transaction, noted that its Canadian operations produce some of the lowest-carbon nickel globally.

Rounds from Vale’s Long Harbour refinery in Newfoundland and Labrador in 2020 had a verified carbon footprint of 4.4 tonnes CO2 equivalent per tonne of nickel, while pellets and powder from the Copper Cliff Nickel Refinery in Sudbury, Ontario recorded a 7.3 tonne-equivalent footprint, the company said.

These figures includes Scope 1 and 2 emissions from mining, milling and refining as well as upstream Scope 3 emissions from inputs, Vale said.

Tesla has spent the past year signing pacts with several producers of battery metals, with a particular emphasis on nickel and lithium.

CEO Elon Musk promised in 2020 “giant contracts” to companies able to produce nickel in an “environmentally sensitive way” amid concerns of an imminent deficit.

Since Musk’s pledge to miners, his company has inked nickel supply deals with the world’s largest miner, BHP, (ASX: BHP) in Australia, with Prony Resources in New Caledonia and with Talon Metals for its Tamarack nickel project in Minnesota, US.

Nickel helps cram more energy into cheaper and smaller battery packs, allowing EVs to charge faster and travel farther between plug-ins.

Prices for the commodity have – not surprisingly – shot to historic records over the last year. In march, they surged by an unprecedented 250% in a day, forcing the London Metal Exchange (LME) to halt trading of the metal.

Musk has repeatedly flagged nickel supply as the company’s biggest concern, as the metal is a key component in batteries for longer-range vehicles. Tesla uses iron-phosphate for shorter-range vehicles.

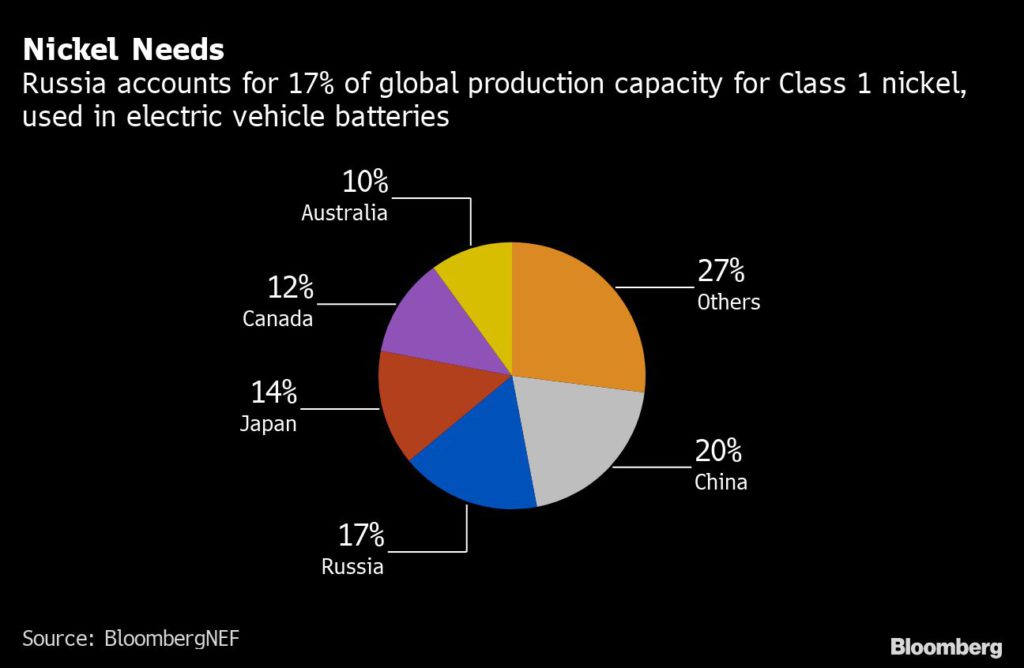

Sanctions against Russia over the invasion of Ukraine have added urgency to secure supplies of the metal, since the country holds about 17% of global capacity for refined Class 1 nickel, the type required for EVs.