In modern underground mines, machines worth millions of dollars sometimes end up buried under tonnes of rock.

Hard-Line, a mining supply company based in Sudbury, Ont., has teamed up with two partners in Australia to make it safer for machine operators to dig out that equipment.

The company specializes in radio remote control systems for heavy equipment, which lets specialists operate machines from a safe distance that can weigh more than 100 tonnes.

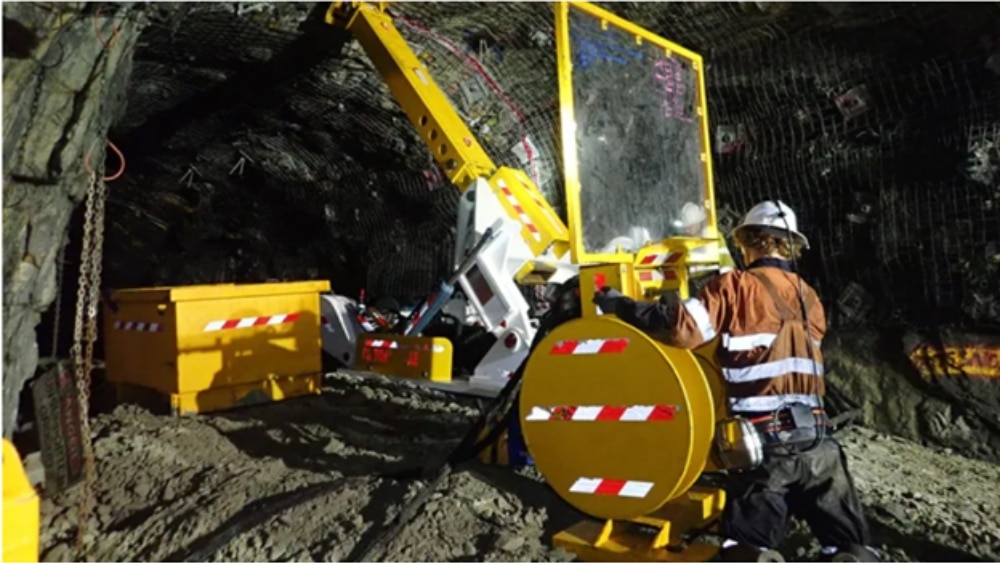

In Australia, Hard-Line has connected its remote controls to a large extraction device made by a company called Beltor Engineering. Their partner Murray Engineering operates a lot of the machinery.

A middle-aged man standing in front of a television screen with the words Hard-Line on it.

Walter Siggelkow is the president of Sudbury-based Hard-Line, which designs radio systems to operate heavy equipment remotely.

“It’s just a really, really heavy-duty set of arms and brackets and feet that basically grip into the rock,” said Hard-Line president Walter Siggelkow, describing Beltor’s machine.

The machines can pull up to 360 tonnes by anchoring themselves to the mine walls and using a winching system to remove debris.

And with Hard-Line’s remote controls, the operator can stand up to 30 metres away where they are safe from falling rock.

“Depending on conditions, it only takes two to five days to pull a machine safely from the rubble compared to outdated methods which can take weeks,” Beltor extraction specialist Ben Robinson said in a news release. Siggelkow explained mining machinery sometimes gets buried after blasting — when workers place explosives to free up chunks of rock that contain ore.

“So the machine goes in to start extracting material,” he said.

“But just keep in mind that this whole area now has not been bolted, or screened, or anything else. So as they start extracting material sometimes the unsupported ground will actually come down. And that’s where you end up with the machine buried.”

A box-shaped yellow device with two large joysticks and a number of buttons in the centre.

Hard-Line designs and manufactures remote controls like this one, to operate heavy equipment at a safe distance. (Jonathan Migneault/CBC)

A buried machine can affect a mine’s profitability because it can slow down or block that process of collecting the ore. The buried machines, which can be worth millions of dollars, can often be repaired, Siggelkow said.

“Some of these machines will have delivery times of, you know, upwards of two years,” he said. “So the scenario of waiting to get a new one is not an option.”

To control them safely, Siggelkow said, Hard-Line builds all of its remote controls and radio equipment from scratch, to withstand an underground mining environment, which is harder on equipment than most other settings.

They also have to be sure the radio signals don’t interfere with each other.

A close up of someone’s hand holding a circuit board.

Hard-Line designs and builds every component of its radio systems. (Jonathan Migneault/CBC)

“One thing that there’s a phenomenon underground in a tunnel is radio waves do not travel through the rock,” Siggelkow said.

“When they hit the rock, they actually bounce off the rock and just carry on down the tunnel.”

Siggelkow said his company is only working with Beltor’s retrieval system in Australian mines, but he would like to bring the technology to Canada.